Struggling to understand graphite blocks and their uses? Let’s break it down simply and help you find clarity.

Graphite blocks are versatile carbon-based materials widely used in industrial and technical applications due to their heat resistance, strength, and conductivity.

Curious about how these remarkable materials are made and where they fit into various industries? Let’s dive in.

The Manufacturing Process of Graphite Blocks: From Raw Material to Final Product?

Leading paragraph: Ever wondered how raw carbon transforms into precision-engineered graphite blocks? The process is as fascinating as the material itself.

Graphite blocks are made by mixing carbon-based raw materials, forming them into shapes, baking, and then graphitizing them under high heat.

The production journey begins with high-purity petroleum coke or anthracite coal as raw material. These are crushed, mixed with a binder like pitch, and formed into blocks. The blocks are baked at around 1,000°C to solidify their structure, then graphitized at temperatures exceeding 2,800°C to achieve their characteristic properties.

Key Steps in Graphite Block Manufacturing

| Stage | Description |

|---|---|

| Mixing | Combining raw materials and binder for uniformity |

| 形にする | Shaping the mixture into blocks |

| Baking | Hardening the structure under high heat |

| Graphitization | Heating to extreme temperatures to form graphite crystal |

This meticulous process ensures graphite blocks exhibit the strength, heat resistance, and conductivity required for demanding applications.

How to Choose the Right Grade of Graphite Block for Your Application?

Choosing the wrong graphite block can cost time and money. Let’s simplify how to pick the right one.

Select graphite blocks based on density, grain size, and application-specific properties like thermal conductivity and strength.

Different grades of graphite blocks serve various industries. High-density blocks with fine grain size are ideal for precision applications like EDM machining. Coarser blocks work well in thermal insulation. Consult with suppliers to match properties like oxidation resistance and conductivity to your needs.

Key Factors for Choosing Graphite Blocks

| Property | Ideal For |

|---|---|

| High Density | Precision tools, molds, electrodes |

| Oxidation Resistance | High-temperature or corrosive environments |

| 熱伝導率 | Heat sinks, industrial furnaces |

Understanding these factors can save you from costly mistakes and optimize performance.

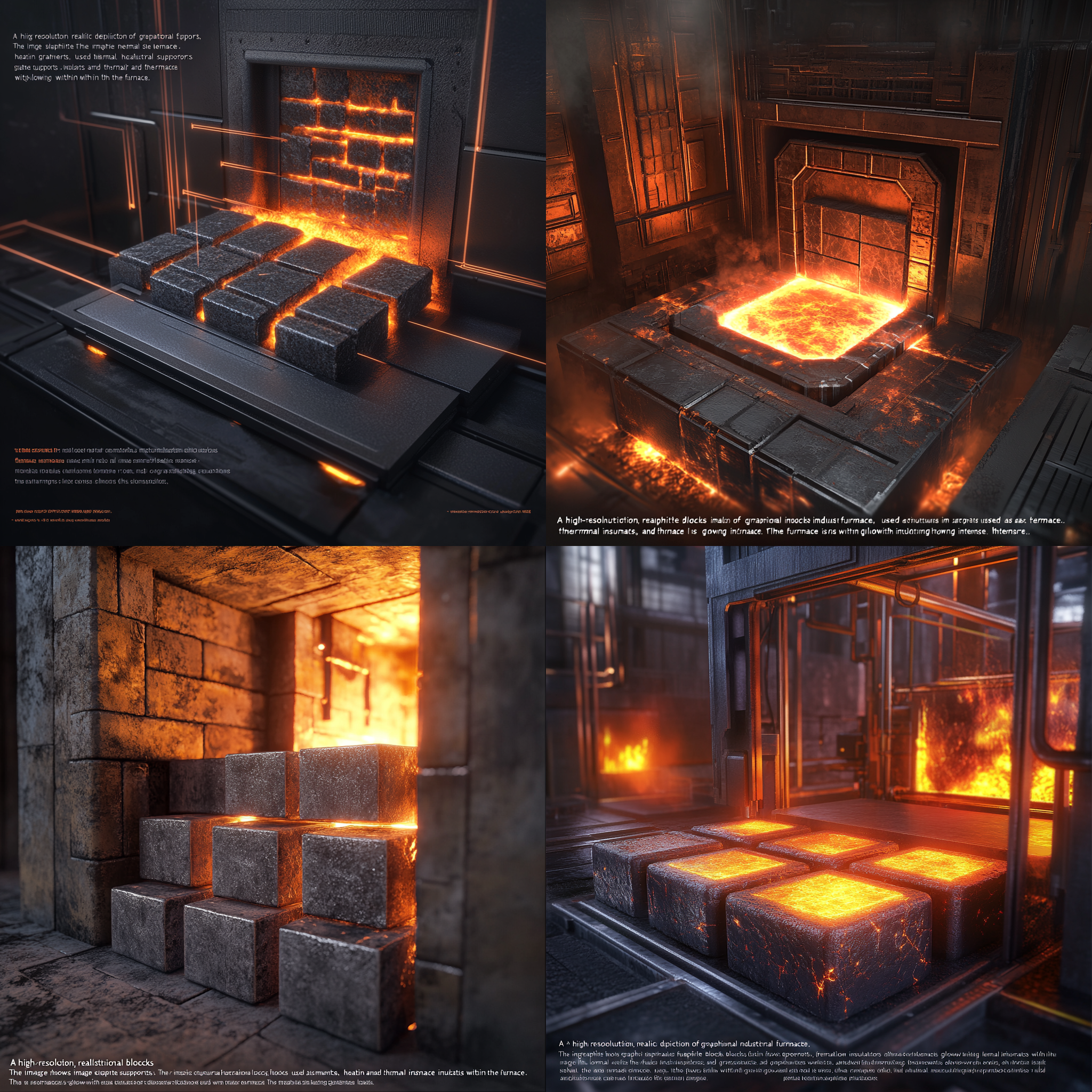

The Role of Graphite Blocks in Industrial Furnace Applications?

Industrial furnaces push materials to their limits. How do graphite blocks stand up to the heat?

Graphite blocks excel in industrial furnaces due to their heat resistance, low thermal expansion, and structural stability.

In furnace applications, graphite blocks are used as structural supports, heating elements, and thermal insulators. Their low thermal expansion prevents cracking under extreme temperatures, and their high conductivity enhances energy efficiency.

Benefits of Graphite Blocks in Furnaces

- Withstand temperatures up to 3,000°C

- Resist oxidation and chemical wear

- Provide excellent dimensional stability

Industries like metallurgy, ceramics, and glass rely heavily on these properties for efficient furnace operations.

Graphite Blocks vs. Carbon Blocks: What Sets Them Apart?

Are graphite blocks the same as carbon blocks? Let’s clear up the confusion.

Graphite blocks differ from carbon blocks in their crystalline structure, processing method, and applications.

While both materials share a carbon base, the graphitization process gives graphite blocks a crystalline structure that enhances their heat resistance and conductivity. Carbon blocks, with a less refined structure, are better suited for lower-cost or less demanding applications.

Key Differences: Graphite vs. Carbon Blocks

| Feature | Graphite Blocks | Carbon Blocks |

|---|---|---|

| Structure | Crystalline | Amorphous |

| Heat Resistance | Excellent | Moderate |

| Typical Applications | High-temp furnaces, EDM tools | Refractory linings, battery anodes |

Selecting between the two depends on your operational demands and budget.

結論

Graphite blocks offer unmatched versatility, strength, and thermal properties, making them essential in industrial and technical fields.